KOMB Engineering, LLC introduced the KOMB EnviroMax 300™ Deepwater Oil and Gas Support Vessel (OSV) in 2019, shortly after the company’s founding. Since its launch, KOMB has expanded the EnviroMax™ series to include a variety of vessels, such as Platform Supply Vessels (PSV), Multi-Purpose Supply Vessels (MPSV), Oil Spill Response Vessels, Fast Bunkering Vessels, Container Vessel Support, Windfarm Service Operation Vessels (SOV), Arctic Oil Spill Response Vessels, and Research Vessels.

As of 2024, KOMB has successfully completed and delivered six vessels from the EnviroMax™ series, with several more in development. These vessels are noted for their environmentally sustainable designs, enhanced mission capabilities, and efficient performance.

The KOMB EnviroMax™ series is engineered for flexibility and adaptability, ensuring that each vessel class maintains high standards of environmental performance, operational efficiency, and mission readiness.

KOMB has introduced a new metric called the usable hull volume ratio, which compares cargo space to total hull volume. For 13 publicly available OSV classes, this ratio ranges from 0.47 to 0.68. In contrast, the KOMB EnviroMax 300™ boasts a ratio of 0.71, the highest among similar vessels.

Another key achievement is balancing minimum hull resistance with maximum deadweight, expressed as (DWT x 35) / (LxBxTxCb). For the 13 leading OSV designs, this ratio ranges from 0.53 to 0.58, whereas the KOMB EnviroMax 300™ achieves a ratio of 0.60.

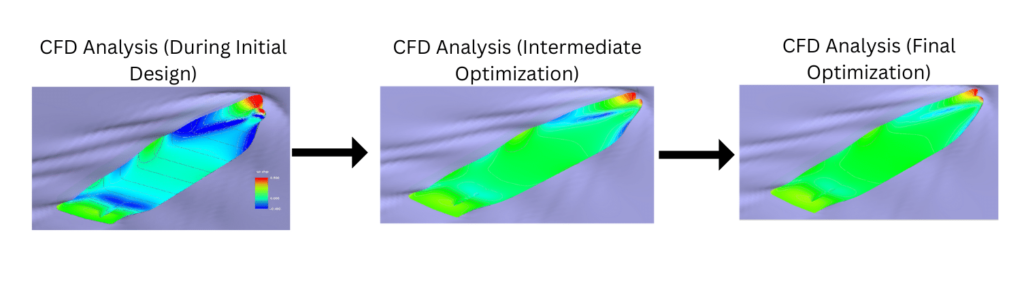

Extensive CFD analyses and resistance optimization were conducted to refine wake flow characteristics, hull shape, and bulbous bow design. The hull’s performance was enhanced by minimizing wave resistance with an advanced bulbous bow, resulting in a 30% reduction in wave resistance. This translates to either higher speed or lower fuel consumption.

The KOMB EnviroMax™ Series demonstrates one of the lowest propulsion power to full load displacement ratios among its peers. While the leading 13 designs range from 0.61 to 0.71 kW / L.Tons displacement, the EnviroMax™ Series achieves a ratio of 0.58 kW / L.Tons.